We are glad to invite you to a Digital Assembly Manufacturing Conference conducted jointly by Proplanner™ and Caresoft Global. At this conference, you can:

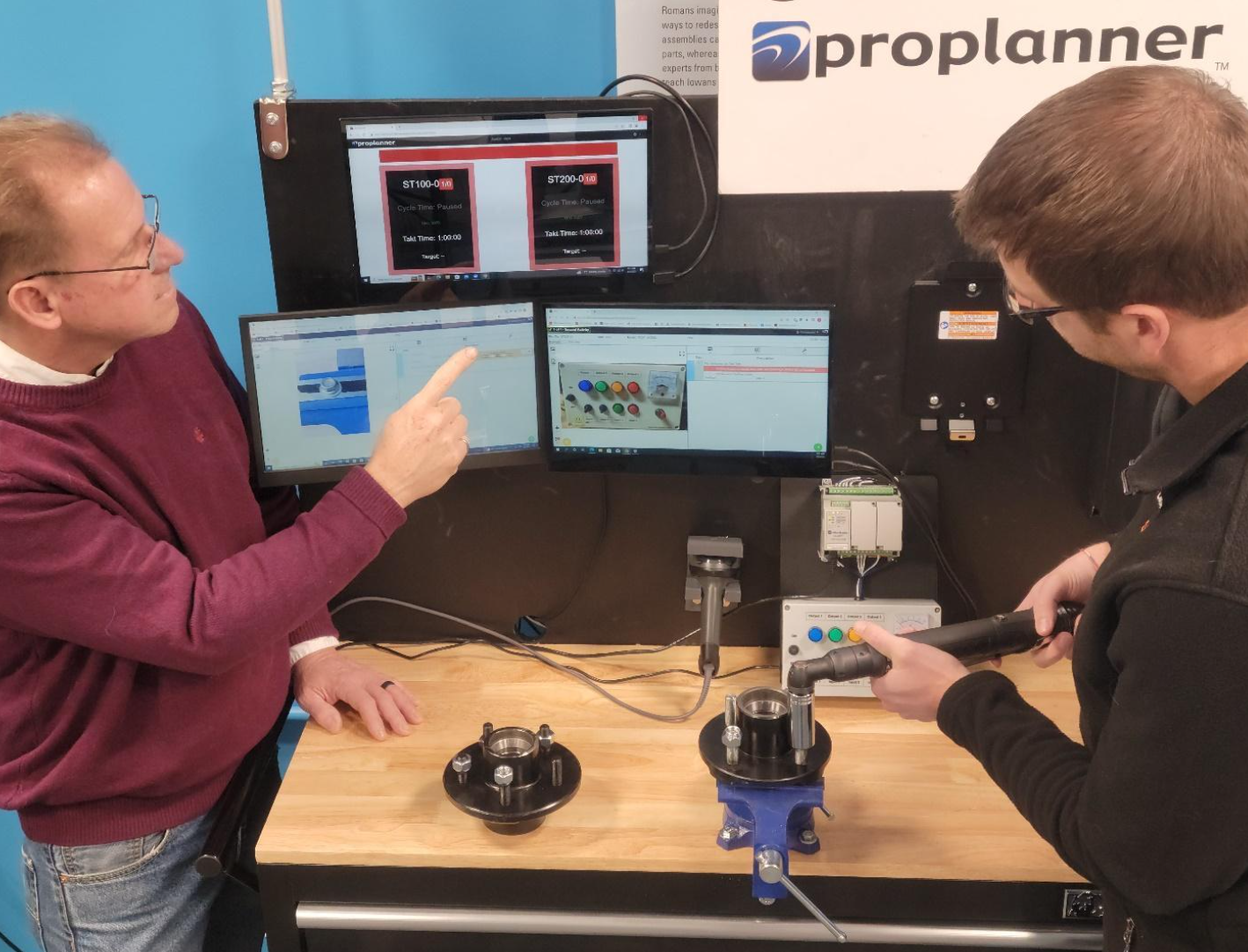

Learn how Proplanner’s monthly subscription assembly Manufacturing Execution System (MES) technology is helping manufacturers quickly and cost-effectively implement a fully integrated digital manufacturing engineering and shop floor execution system.

Interact with Proplanner and Caresoft’s experts, that can help you leverage technology to reduce assembly costs and increase quality.

Ask for a detailed agenda as a PDF copy.

Details:

Conference and hands-on demo: Tuesday, May 16th, 2023

Venue: Venue: Brookfield Conference Center, Brookfield, Wisconsin.

How to register? Click this link below:

Contact Dave Sly ( [email protected] )

We hope to see you at the conference.

Note: There is no charge to attend this event, which is an in-person event to experience a hands-on demo. There is no online track.

What Will I Learn?

DISCOVER: How monthly subscription assembly Manufacturing Execution System (MES) technology is helping manufacturers quickly and cost-effectively implement a fully integrated digital manufacturing engineering and shop floor execution system

- Learn how to set up low-cost shop floor workstations with simple, readily available hardware (touch-screens, Intel Nuc’s, Android Scanners, Rasberry Pis)

- Author and deploy auto-configured work instructions with order-specific part and tooling callouts and labor requirements.

- Learn how to quickly and efficiently track Actual vs. Expected labor for highly configured assemblies.

- Connect Industrial Internet of Things (IIoT), quality control/traceability, and work instruction initiatives.

- PLCs, scanners, Pick-to-light systems, DC torque tools

- Non-Conformance Report integrated with defect tracking and work instructions

- Product genealogy and component serial validations

- Learn how to deploy collaboration technologies between the shop floor and planning (Pictures, Videos, CAD models, SMS notifications)

- Manage worker task qualifications and station assignments

- Capabilities of a Quick and Easy Andon System you can deploy on TV Screens, laptops, tablets and cell phones.

Why Should You Attend?

If you want to learn how to leverage cloud and IIOT technology to quickly bring unit-specific instructions and shop floor data collection and control to your assembly lines with a very low startup cost.

- Improve traceability of manufacturing data, shop floor workers, and production events.

- Reduce the effort of the engineering and planning teams for managing process sheets and automation initiatives for highly configured assemblies.

- Build and deploy IIoT capabilities with an instant payback using monthly subscription cloud-based solutions.

- Reduce launch times for product design changes and process improvements while enhancing access to documents, pictures, videos, and CAD models.

- Experience quicker and more meaningful and traceable communication between engineering and production

- Gain hands-on experience with real systems deployed at world-class Fortune 100 manufacturing firms – recently now cost-effective for SME’s (Small and Medium Enterprises)

- Enhance productivity communications with simple and effective web-based Andon systems.