Commercial Vehicles

From Greenfield Programs to Driving Compliance Strategies and Everything In Between.

We work with some of the world’s largest commercial vehicles and bus & coach manufacturers in the areas of product design, design validation, and industrial engineering programs. Our teams are working closely with our customers on a wide range of greenfield projects, new product development, and ongoing engineering data processing.

Competency Areas

Suspension, Engine & Electrical

- Chassis frame

- Underframe assembly

- Engine mounts

- Drivetrain calculations

- Vehicle architecture

- Hydraulics

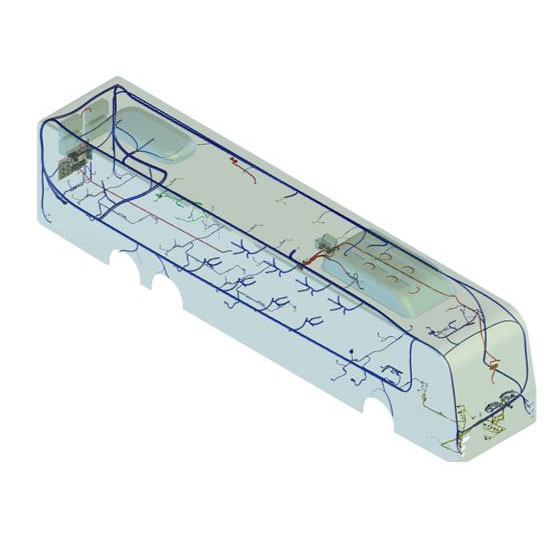

- Harness components

- Power distribution systems

- Schematics

- Wire harness design and costing using costCompare tool

Exterior and Frames

- Body panels

- Frontend modules

- Rear modules

- Bumper assemblies

- Floor assemblies

- Roof assembly

- Door assembly

- Front and rear frames

- Headlamps

- Frame and tubular structures

Interior Trims

- Dashboards

- Driver cabins

- Door trims

- Floor

- Covers and light assembly

Analysis and Services

Product Engineering

- Concept feasibility

- Interference and clearance checks

- Homologation requirements

- DFMA, Gap & Flush analysis

- Power distribution strategies

- Engineering change management

- Electrical and electronic component designs

- Configuration management

- Build support and design optimization

- Structural and CFD analysis

Manufacturing and Quality

- Line balancing and ergonomics

- Time study and labor standard development

- Plant-wide continuous improvement programs

- Process improvements in assembly lines

- PFMEA and control plan

- Productivity improvements and manpower optimization

- In-plant logistics optimization

- Value stream transformation

- New assembly line process design

Aftersales

- Operator manuals

- Repair and service manuals

- Parts catalog

- Electrical troubleshooting procedures

- Product animations

- eLearning and training material for dealers

Transform your vehicle programs with us.

Leverage our expertise in design, validation, manufacturing, and even compliance standards such as material, safety standards, and emission norms.

Our knowledge runs deep

- We have worked on Euro-6 adherence programs

- We have rationalized existing components within the electrical distribution system as part of the new product launch

- We have delivered drawings for layout, homologation, parts & assembly, wire harness, and electrical schematics

- We have worked in electric, hybrid and conventional single & double-decker buses

- We have been recognized by Navistar International as a Diamond Supplier for the year 2016 and 2017 for our work in industrial engineering, logistics, and process optimization

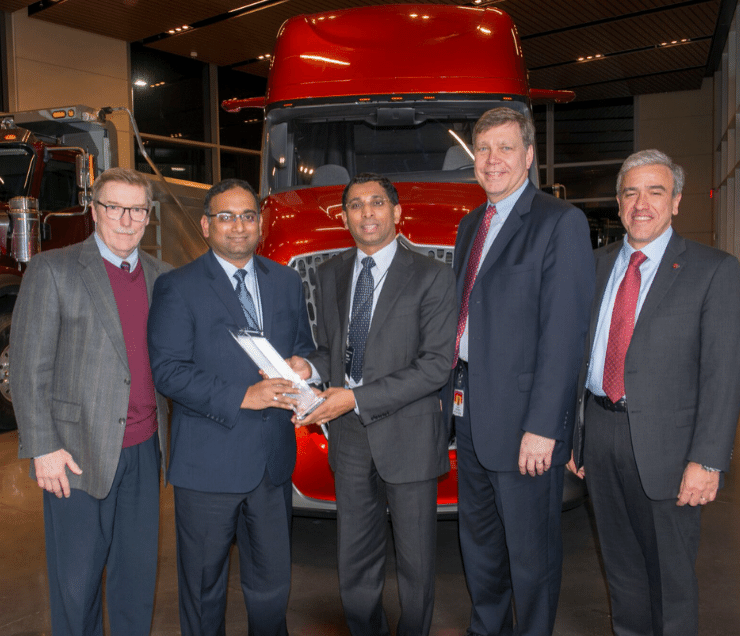

A Two-time Navistar Diamond Supplier Award Winner.

Photo: Caresoft’s leadership team with Troy A Clarke, CEO, President, and Chairman of the Board for Navistar International Corporation.

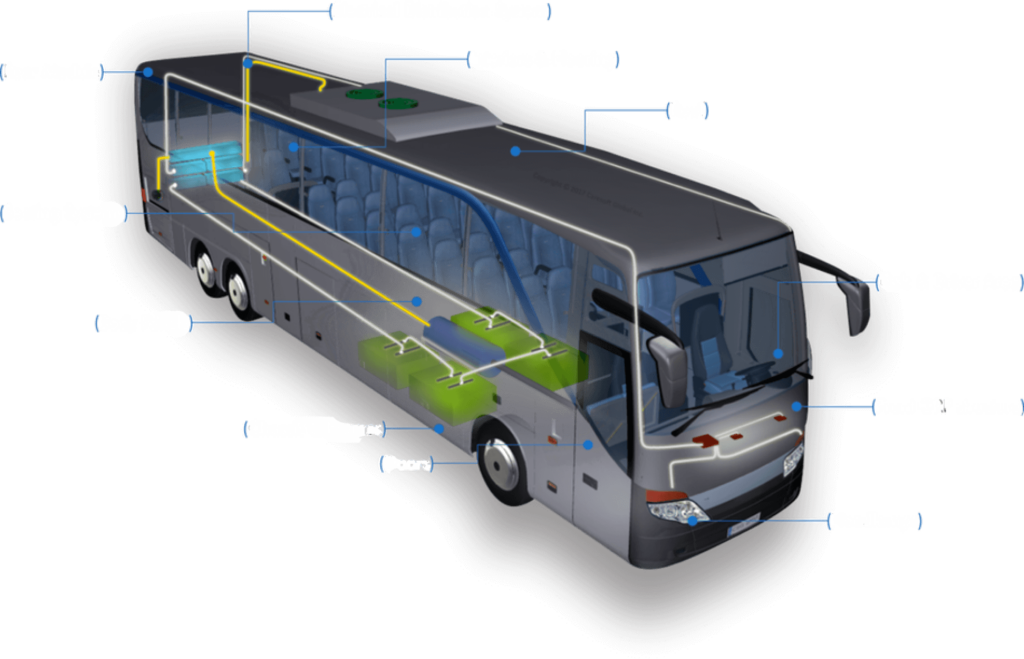

Proven expertise in every aspect of the bus.

Pillars, Tubes & Pipes, Brackets, Reinforcement, Wheel arches module, Frame module, Lateral face final buck, the trim mounting assembly has been our forte. Plan for the roof to address the safety, comfort, strength, and load distribution varies between bus to coach to inter-city to intra-city buses. We have experience in supporting some of the most complex roof designs and integrating them with the overall structure of the bus.

Fleet owners have different customization needs depending on their geography and demographics. All these technological, economical, and environmental aspects lead to variants for the same platform which adds to the increasing complexity of the wire harnesses.

Ready to get started?

We are a technology-driven global engineering solutions company addressing challenges relative to benchmarking, product development, cost optimization, manufacturing, and aftermarket for major automotive OEMs, off-highway, commercial vehicle manufacturers, and their suppliers. Our award-winning technologies combined with highly evolved processes enable our customers to gain actionable insights that accelerate R&D programs, fuel growth decisions, cut costs, and improve efficiencies.