Award-Winning Full Vehicle Digital-Twins

Take advantage of the integration of world-class engineers, subject matter experts, award-winning technologies, and processes to drive actionable results and achieve your benchmarking goals.

Give Context and Purpose to Your Benchmarking Data

We have taken the Automotive Benchmarking process to a whole new level. Using highly accurate Digital-Twins of full vehicles prepared using our Patented Technology, we can help you assess and benchmark a competitor’s entire vehicle or a component relative to design fitness, lightweighting targets, and program-level cost reduction goals. Take advantage of actionable insights that are available exclusively from Caresoft Global.

Data

Knowledge

Actionable Results

Explained with videos

Digital-Twins Technology for Benchmarking

DeltaCosting™ approach to drive Cost Reduction.

Global Technology Centers

Drive Actions, Not Data

Exclusive Advanced Data

Gain actionable insights with our exclusive advanced data on EV tech, electrical systems, BIW, and much more.

Traditional Teardown

Access highly detailed teardown data along with several unique perspectives such as component-level comparisons.

Drive Cost Reduction Programs

Drive cost reduction, eliminate waste, and refine design fitness.

Customer acceptance rate of Cost Reduction ideas for implementation: >75%

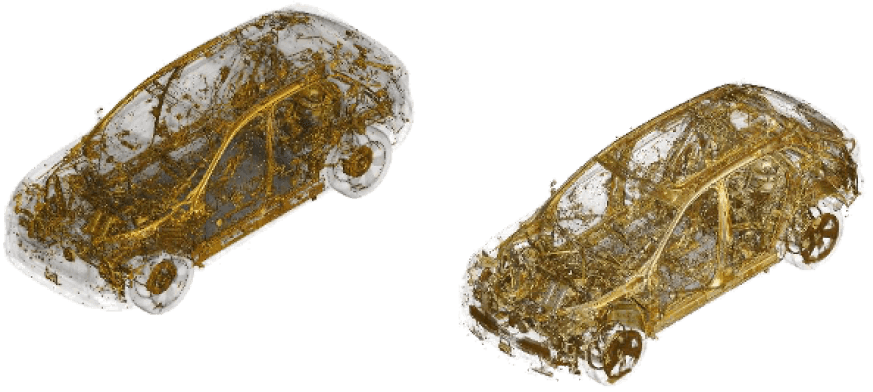

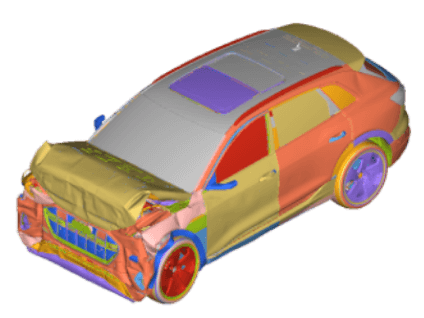

The Digital-Twin Technology and Process

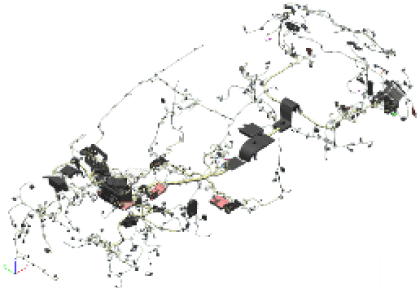

Routing

Deliverables and Packages

Digital-Twins and EV Technology Insights

Insights to optimize lightweighting and packaging strategies, crashworthiness of design and more.

- Full Vehicle Digital-Twin Data:

- 3D CAD models for full vehicle, systems and subsystems with 3D Harness routing

- Full vehicle CAE data, crash models with frontal crash simulation

- CFD - External aerodynamic analysis

- CFD - HV Battery coolant flow analysis

Insights on:

Strategize lightweighting and packaging strategies

Alternate material strategies

Crashworthiness of design

NVH, stiffness studies with different boundary conditions

Harness routing

Understand battery architecture, thermal and power retention strategies, battery management system integration methods from the latest EVs around the world.

HV battery architecture report

HV battery cell studies

E-Motor advance studies

Insights on:

HV battery structural part definition

HV thermal strategies - Microstructure - Anode/Cathode materials

Power retention strategies

Stator and Rotor construction material studies

Strategically defined magnetic field strength

Battery design and safety

BMS integration

Advanced Data, Teardown, and Motorshows

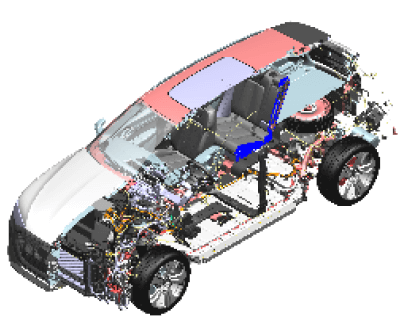

Exclusive insights into BIW, Chassis kinematics, HV/LV harness architecture and lot more.

3D surface point-cloud data

Ergonomic assessments 2D Layout

BIW studies

Chassis studies

Electrical architecture studies

Vehicle electronics - HMI

Full vehicle cooling circuits

Insights on:

Modularity, configuration, space claim analysis, and packaging

Chassis kinematics

Thermal management system design and performance

Coolant flow rate, heat dissipation in different modes

HV/LV harnesses architecture

Communication protocols

PCB to Pin level information of modules

Smart features of HMI unit

Material grade and composition studies

Mixed-material strategies

Traditional teardown data cataloged relative to BoM, component-level metadata, eye-catching features, etc.

- Parts photographs

- Bill of materials

- Mass and dimensions

- Supplier information and manufacturing details

- Material classification (from teardown data)

- Exploded views

Insights on:

Comparative study at component level

Unique and eye-catching features

Specific components and its assembly location

Weight and material inference across components and commodities

Physical attributes such as mass, dimensions, supplier, etc.

Highly detailed photos of the latest vehicles launches across global motor shows.

Access highly detailed photographs of vehicles launched in global motor shows

Including new launches, facelifts, and concepts

Perform side-by-side comparisons

Motoview.com and Iceberg 3.0

- Motoview.com for free photos of exteriors

- Motorshows module inside Iceberg 3.0 for greater details

Full Vehicle Digital-Twin to DeltaCosting™

DeltaCosting™ is a process to identify cost reduction opportunities between two competing vehicles to develop the most efficient and cost-effective way to meet the engineering goals using industry expertise, vehicle digital twin data, and first principles.

By Steve Kensett, Former Chief Body Architect, General Motors

Ready to get started?

We are a technology-driven global engineering solutions company addressing challenges relative to benchmarking, product development, cost optimization, manufacturing, and aftermarket for major automotive OEMs, off-highway, commercial vehicle manufacturers, and their suppliers. Our award-winning technologies combined with highly evolved processes enable our customers to gain actionable insights that accelerate R&D programs, fuel growth decisions, cut costs, and improve efficiencies.