Aftermarket and Parts

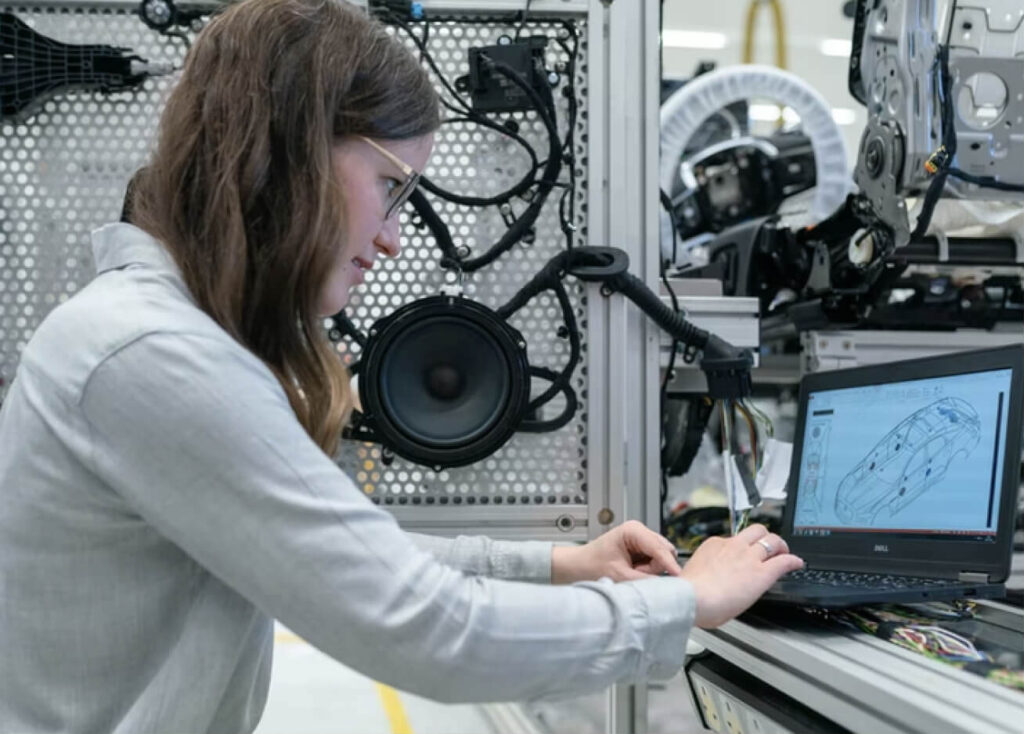

Our integrated approach to parts management addresses design, manufacturing, and aftersales support.

Increasing efficiencies in global parts management.

Our approach combines business analytics with custom applications to address each functional area that brings efficiency in parts management. For e.g., a tool for catalog maintenance with part family and noun nomenclature.

Our software – costCompare for wire harness costing is used by global OEMs. costCompare significantly reduces the time taken to cost harness and generate reports based on material, machining and labor costs instantly.

We have mined 100,000+ parts that were distributed across 75+ commodities using an exclusive tool to group parts with similar attributes and aid rationalization. With the combination of tool and service we eliminated 10,000+ duplicate parts from the inventory (Soft and hard savings)

Addressing the industry pain points

Consolidation after an M&A event:

- Addressing duplicate parts in service parts population

- Parts duplication arising out of new product offerings

- Duplicate parts arising from purchase of OEM products and re-branding without validating existing part libraries

Inventory management:

- Overstocked depots

- Engineers, buyers, warehouse operations and quality staff spending unnecessary time on the maintenance of the excess parts

- Locked-up capital owing to excess inventory

Differential part pricing across the supply chain:

- The same part existing under different part numbers and price points leading to confused dealer choices

- The suppliers taking advantage of the confusion and supply the same part under different part numbers to the OEM, usually at different price points at different locations

For a global OEM, we have performed pricing analysis for 200,000+ parts across 120+ commodities in a short span of 18 months.

A platform-based approach for parts management

Solution

Change management

Parts consolidation

Service kits management

Parts catalog

Pricing management

Production Part Approval Process (PPAP)

eCommerce

Service stack

Change management processing support

3D design and drawing creations

Release in PLM/PDM

Data mining

Parts rationalization

De-complexity

Physical kit validation

Innovative marketing kit development

Obsolescence and overstock support for kits

Noun validation and classification

Catalogue maintenance

Smart pricing

Should costing

PFMEA and controls plan documentation support

PPAP processing

APQP facilitation

Data analysis to build an e-commerce tool

Attribute gathering and cleaning

Application stack

Change management tool

Parts consolidation tool

Service kits tool

Parts catalogue

BOM/Harness costing

PPAP tool

e-commerce tools

CAE, CFD analysis and simulation

Meshing

- Re-manufacturing support and publications

- Reverse engineering for resourcing

- Service parts design support

- Standard parts design kits validation — kit tool

Change management & release support

- Engineering change updates on service parts

- Release activity in PDM based on engineering changes

- Parts database maintenance

Purchasing

- Should costing support for supplier selection for new parts and supplier negotiation for existing parts – RFQs

- Prototype parts procurement

- Sourcing and supplier management

- ISIR processing for vendor parts – quality module

Sales and after sales

- Parts catalogue management

- Parts description standardization

- Sale order processing

- Warranty claims processing

- Service quote generation

Cost savings

- Parts rationalization

- ABC analysis

- Inventory management

- Smart pricing

- De-complexity

- Value stream mapping

Ready to get started?

We are a technology-driven global engineering solutions company addressing challenges relative to benchmarking, product development, cost optimization, manufacturing, and aftermarket for major automotive OEMs, off-highway, commercial vehicle manufacturers, and their suppliers. Our award-winning technologies combined with highly evolved processes enable our customers to gain actionable insights that accelerate R&D programs, fuel growth decisions, cut costs, and improve efficiencies.